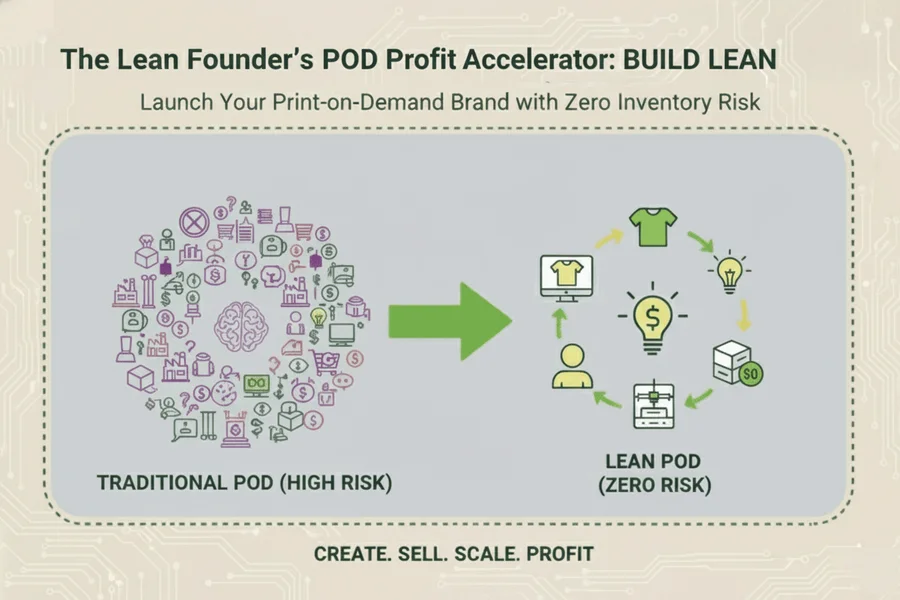

The Print-on-Demand (POD) market is in the middle of an explosive growth cycle, projected to expand at a powerful 26% Compound Annual Growth Rate (CAGR) through 2034. This massive tailwind makes it the ideal environment for the modern solopreneur. The barrier to entry, once measured in thousands of dollars for inventory, is now nearly zero. However, success is not guaranteed merely by launching a product; it demands a ruthless, capital-efficient, and strategic approach—the core tenets of Lean methodology.

For the early-stage founder, the first three decisions—how to produce, what to sell, and which technology to use—determine the long-term health and profitability of the business. These choices are the foundation of the operational stack and must be made with an unwavering commitment to minimizing risk and maximizing learning speed. Here is the lean mandate for launching your custom apparel brand without drowning in debt, inventory, or operational complexity.

The Trap of the Printer: Why "Partner First" is the Only Lean Mandate

The decision to produce prints in-house versus outsourcing fulfillment is the first major hurdle for a founder. This choice is an early litmus test of a founder’s commitment to the Lean Principle of delaying irreversible decisions. While the siren song of lower long-term per-unit costs might tempt you to invest in your own equipment, a lean approach mandates an uncompromising "Partner First" strategy.

The costs of self-production extend far beyond the initial price tag, creating an operational burden that prematurely shifts the founder's role from CEO and marketer to floor manager and technician:

- High Upfront Capital: Entry-level Direct-to-Garment (DTG) or Direct-to-Film (DTF) equipment can range from $3,000 to $7,000 for professional-grade machines. This capital is not merely a sunk cost; it is cash that should be allocated to high-leverage growth activities like A/B testing of ad creatives, professional design services, and robust market research. Allocating this cash to equipment before market validation is the antithesis of lean.

- The Hidden Labor Sink (Opportunity Cost): Operating your own machine demands significant fixed labor that cannot be ignored. DTF and DTG machines, for instance, require at least 20 to 30 minutes of daily maintenance to prevent costly clogs and damage. This labor commitment introduces high opportunity costs, diverting time and focus away from growth activities such as strategic marketing, content creation, and analyzing customer feedback. Trading this time for marginal production savings is a poor calculation.

- Operational Risk and Infrastructure: Owning a printer introduces the systemic risk of costly equipment downtime, requiring immediate repair and technical troubleshooting. Furthermore, it necessitates managing a complex supply chain of inks, films, pretreatment chemicals, and blank garments, which ties up working capital and requires dedicated storage space.

The Lean Solution: Outsourcing Operational Risk.

Your time is a finite growth resource. Every minute spent troubleshooting a printer is a minute diverted from high-leverage activities like design creation and strategic marketing. The "Partner First" solution is to outsource the operational risk entirely. By starting with a third-party fulfillment partner (such as Printify, Printful, or Gelato), you instantly eliminate all upfront capital expenditure, inventory risk, maintenance burdens, and the need for complex, costly infrastructure.

This immediate automation allows you to focus 100% of your energy on the single most important early-stage activity: validating the market and finding product-market fit, not managing logistics.

Designing for the Hyper-Niche: Escaping the 20% Margin

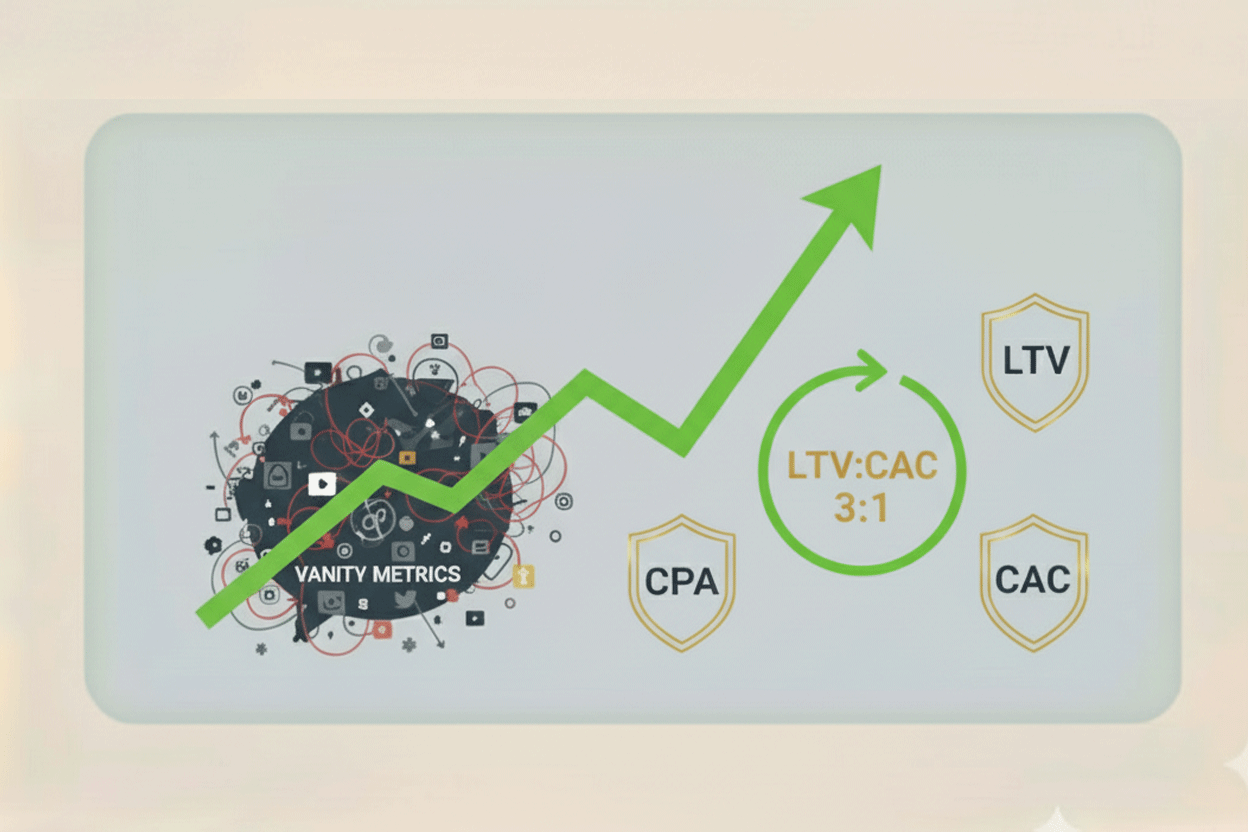

In the crowded POD space, launching a generalized product guarantees you will land in the highly competitive commodity zone. The analysis shows that the industry's average profit margin hovers around 20% for generic products, a thin margin that leaves no room for error. To build a sustainable, profitable business, you must escape this ceiling and justify premium pricing.

To achieve this, move beyond broad appeal and adopt the Intersectionality Principle when choosing and designing for your niche:

- Broad Niche (Low Margin, High Competition): Dog Lovers or Gardeners.

- Hyper-Niche (High Authority, High Profit Potential): Eco-conscious urban beekeepers or Sustainable cottagecore gamers.

Success is found at the intersection of two or more interests. This hyper-specificity achieves two critical objectives, allowing you to charge 50-100% more than the commodity price:

- Deep Resonance and High Conversion: Your product must resonate deeply with a small, highly passionate demographic, feeling custom-made for them. This level of emotional connection radically improves brand loyalty, conversion rates, and the Customer Lifetime Value (CLV).

- High Barrier to Entry for Competitors: Competitors focused on broad niches will find it difficult and uneconomical to replicate your highly specific language and designs.

The Lean Design Mandate: Do not create a design that many people will like. Create a design that a few people will love.

Choosing Your Anchor Product Print Technology

Once your hyper-niche is defined, you need to select a printing technology that supports high quality and low volume. For the lean founder relying on a fulfillment partner, the primary choice is between Direct-to-Garment (DTG) and Direct-to-Film (DTF). This decision is critical because it impacts the durability, feel, and fabric compatibility of your final product.

| Technology | Best For | Strategic Advantage | Fabric Compatibility |

|---|---|---|---|

| Direct-to-Garment (DTG) | Complex, photorealistic designs, high detail | Exceptional detail, smooth color gradients, and a soft, "part of the fabric" feel. | Optimal for 100% cotton (ring-spun/combed cotton is best for ink absorption). |

| Direct-to-Film (DTF) | High-durability, vivid prints on synthetics or dark garments | Versatility, highly durable, often lower initial cost for small runs, thicker texture. | Works on any fabric blend, including polyester, activewear, and tricky fabrics. |

The Strategic Choice: DTF has emerged as the strategic asset for the modern founder due to its versatility and robustness. It is ideal if your hyper-niche requires activewear, hoodies, or other poly-blends. DTG remains the premium choice for a superior "hand-feel" on high-quality natural cotton.

Your Lean Action Plan: Zero-Touch Launch

This first phase—the "Build Lean" phase—culminates in a fully automated, risk-free launch stack:

- Define Your Hyper-Niche: Apply the Intersectionality Principle.

- Select Your Partner: Choose a fulfillment service (Printify, Printful, etc.) that offers both DTG and DTF printing on sustainable and high-quality materials.

- Establish Your Tech Stack (The Zero-Touch Automation): Connect your storefront (Shopify is the industry leader, hosting 62.8% of POD stores) to your fulfillment partner. This guarantees instant, zero-touch order fulfillment, freeing you to focus exclusively on marketing.

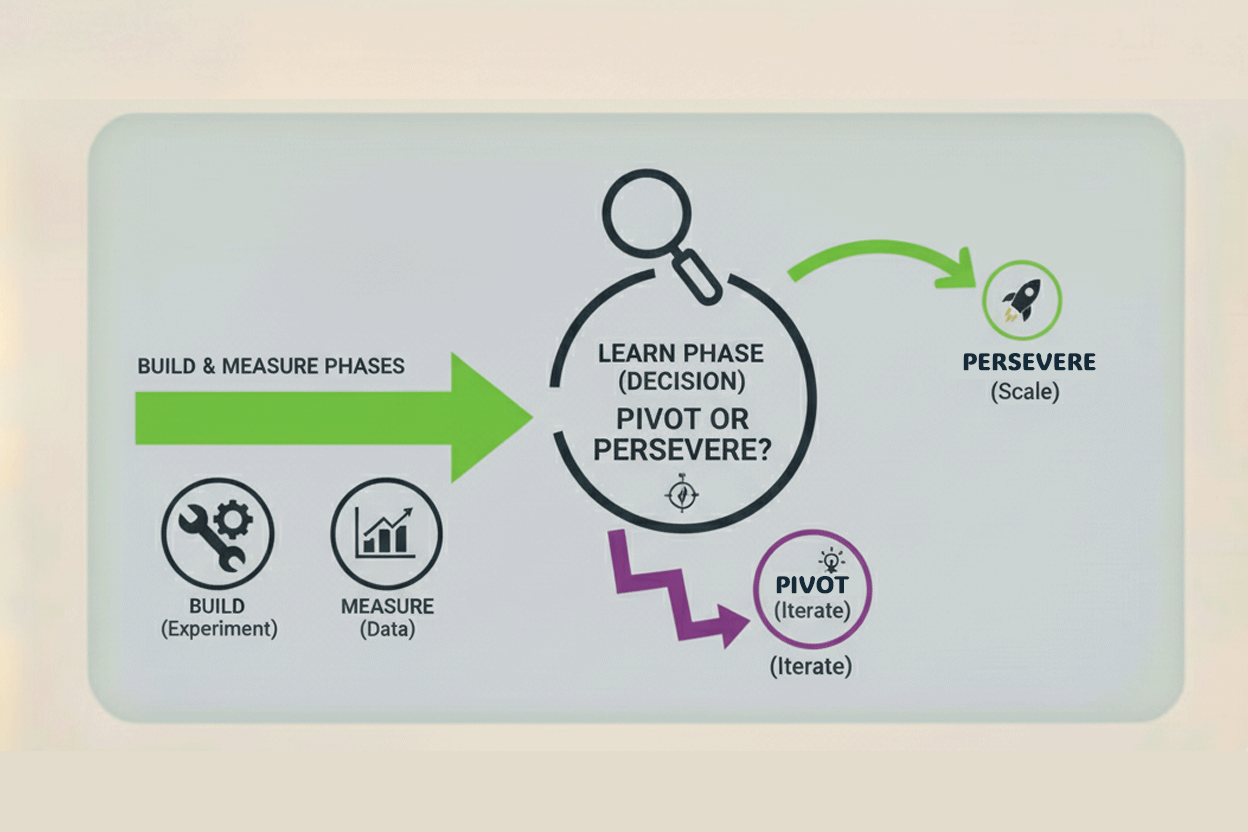

This approach enables you to Build Lean—dedicating capital and time only to the most critical asset: market validation. By eliminating inventory risk and operational overhead from day one, you have created a mechanism for rapid product iteration.

Ready to test your designs for profit? In Part 2: MEASURE WHAT MATTERS, we will detail how to leverage AI tools and high-conversion SEO to validate your designs and escape the commodity trap.

No comments yet

Be the first to share your thoughts on this article!